January 27, 2026 • 8 min read

Wastewater treatment: A critical challenge for renewable diesel production

Around the world, the energy transition has triggered massive demand for renewable energy. Renewable diesel is one of several vital ‘biofuels’, or renewable fuels, that enable the production of this energy. However, refinery operators face critical challenges in treating wastewater resulting from renewable diesel production.

For a start, the level of organic contaminants in this wastewater – often expressed as chemical oxygen demand (COD) – can be 10 to 100 times higher than is typically found in a petroleum refinery.

Renewable diesel wastewater also tends to have a lower flow rate and requires a treatment intensity well beyond what is typically used at modern oil refineries. In practical terms, the higher COD concentrations combined with these lower flow rates mean that a wastewater treatment plant designed for a 500,000 barrels per day (bpd) oil refinery would only be able to handle the wastewater from a 40,000–50,000 bpd renewable diesel refinery.

That’s because wastewater from renewable diesel refining also contains a high concentration of total oil (oil-in-water), typically between 7,000 and 50,000 milligrams per liter, and requires pre-treatment similar to that used for oily wastewater from conventional refineries. Additionally, plant hydraulics such as piping and pumping may need altering to properly convey the lower flow rates, plant hydraulics such as piping and pumping may need altering to properly convey the lower flow rates.

Understanding the rise in demand for renewable diesel

For refinery owners planning to meet the demand for renewable diesel, it’s clear that cost-effective and efficient new wastewater treatment solutions are urgently needed – and we’re on the case.

As a first step, it’s important to understand what’s behind the rise in renewable diesel demand.

Fuels like biodiesel and renewable diesel are produced from a wide range of feedstocks, including vegetable oils (from soybean, cottonseed, coconut, nuts, canola and sunflower), used frying oil, algae and even animal fats such as waste tallow.

Over a century later, renewable diesel is again being refined and sold as a more sustainable fuel for diesel engines. That’s because renewable diesel combustion produces significantly lower greenhouse gas emissions compared to petroleum-derived fuels.

Renewable diesel is produced by hydrotreating a renewable feedstock, using hydrogen. Lower-carbon credentials are further improved when the hydrogen is produced using renewable electricity.

This process yields a fuel product chemically identical to diesel derived from fossil fuel. When manufactured in compliance with ASTM D975 fuel standards, renewable diesel is a sustainable, clean-burning fuel that can be used in existing diesel engines without the need to modify those engines. It has enormous potential as a transport fuel and a potential renewable hydrocarbon feedstock for parts of the petrochemicals industry.

Biodiesel is typically blended with diesel derived from fossil fuel, often at a ratio of 20 percent biodiesel to 80 percent fossil-fuel–derived diesel. To produce this blend (ASTM D6751 B100 fuel), the feedstock goes through a process called transesterification, which converts natural fatty acids or triglycerides into mono-alkyl esters and glycerin. Typically, around 100 kilograms (kg) of fatty feedstock plus around 10 kg of alcohol produces 100 kg of biodiesel product.

The glycerin by-product from biofuel processing is a valuable input for numerous chemical products, including soap, pharmaceuticals and explosives. However, not all of this glycerin by-product can be recovered. When mixed with other organic residues, this results in wastewater with a high COD.

“As the energy transition progresses, we predict significant growth in renewable diesel production and processing. The refinery wastewater plants will be much larger, and new treatment approaches will be needed. This is a challenge for refinery owners planning to establish or expand renewable diesel processing, but also an opportunity to expand to other renewable fuels.”

Andrew Hodgkinson, Water Processing Engineering Technology Manager, Worley Consulting

Even a relatively modest 50,000 bpd renewable diesel refinery may require the processing of as much contaminant load (represented by COD) as a much larger mineral oil facility. This is significant, as it could mean the refinery needs a completely new wastewater facility, not just a minor upgrade.

Even though renewable diesel wastewater may be more contaminated than traditional oil refinery wastewater, it is also biodegradable. We can extract further value through biological treatment methods like anaerobic digestion, where microorganisms treat the wastewater while also producing a valuable renewable fuel by-product: renewable natural gas (RNG).

It’s also worth noting that the air emissions from renewable diesel wastewater are considerably less toxic than mineral oil refinery wastewater. These emissions don’t require elaborate capture and treatment systems often needed to control benzene, toluene and xylene-class volatile organic compounds arising from typical mineral oil refining.

Producing renewable diesel with renewable (green) hydrogen

Renewable diesel production often requires hydrogen, which can be produced in several ways. However, truly lower-carbon renewable diesel requires renewable (green) hydrogen produced using renewable energy.

Renewable (green) hydrogen can be made from RNG or by electrolyzing water using renewable electricity. Both pathways require high-purity water, and this water requirement can significantly exceed the capability of most refinery boiler feedwater systems. The water quality requirements for electrolytic hydrogen are particularly strict. As a result of these factors, we predict a growing demand for dedicated water supplies and demineralization facilities.

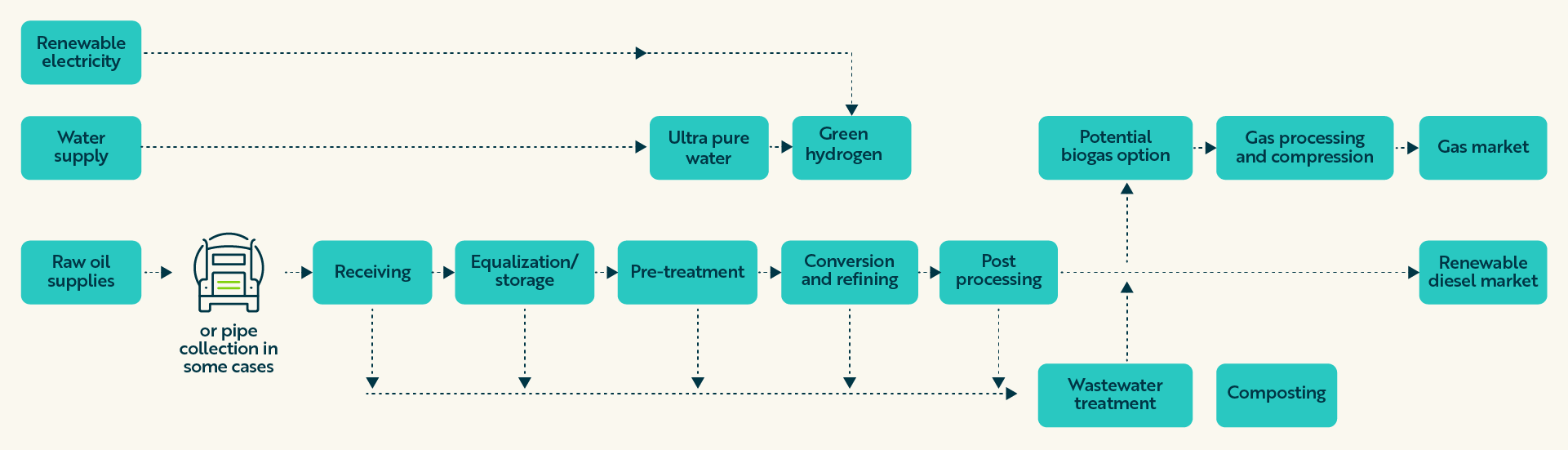

The diagram below shows an example of a renewable diesel production sequence including wastewater treatment and RNG production. The renewable (green) hydrogen included in the refining sequence would likely require demineralized water for its production.

Hover to zoom. Click to view larger (opens in a new tab). Tap to view larger (opens in a new tab).

Analyzing alternative options for wastewater treatment

The residual organic waste from renewable diesel production makes suitable ‘food’ for bacterial decay. An anaerobic digester (effectively a large, airless biological reaction tank) fed with residual organic waste can produce raw biogas, which can then be further refined into RNG.

Although anaerobic digesters have been used to treat wastewater for over a century, they have rarely been used in oil refineries – and they have not always been optimized for RNG production.

Our team of wastewater engineers has decades of experience designing and operating anaerobic processing and biogas production systems. The optimum design so far is a hybrid of several similar processes from other industries where these technologies are widely used. This typically follows a sequence like the following:

Statistic Cards

Leveraging the strengths of anaerobic biological processes

Anaerobic processes require much less electricity to treat similar amounts of organic waste than would be needed in traditional aerobic biological systems, so they produce significantly less carbon dioxide. The methane yield also creates carbon dioxide offset opportunities, and waste biological sludge production can be up to seven times lower than in traditional systems.

We’re also experienced in many other techniques beyond the use of anaerobic processes to manage renewable diesel wastewaters. These include:

- Oil separation: American Petroleum Institute Separator (API)/Corrugated Plate Interceptor (CPI), Dissolved Air Flotation (DAF)

- Clarification-Flocculation

- Biological treatment: Activated Sludge Process (ASP), Anaerobic, Moving Bed Biofilm Reactor (MBBR), Membrane Bioreactor (MBR), etc.

- Sludge management

- Tertiary treatments: membranes, Total Dissolved Solids (TDS) removal, Ultraviolet Disinfection (UV), etc.

In our years of experience, we’ve learned how to manage and predict the performance of each of these operations to optimize the value of wastewater treatment facilities as demand for renewable diesel increases.

If wastewater treatment does not operate reliably and efficiently, the associated costs can erode profitability in other parts of a business.

Reliability and efficiency are critical in all aspects of wastewater treatment, including odor control, solids handling, and chemical demands. Our process technologists and plant designers know this and consider these factors in all the work they do.

Water solutions: Critical for refinery owners looking to decarbonize

Refinery owners planning to meet the demand for renewable diesel will need to consider substantial capital investments. Some of the required components may not be core to your business – and you want your time focused on your market products, not the waste streams, for example.

Our water sourcing and wastewater treatment solutions can be delivered using alternative commercial models, including build-own-operate.

Refinery owners often find solutions by integrating or reusing processes within existing refinery water and wastewater facilities, though some cases call for an entirely new system.

As you explore your options, you can count on us for quality engineering, construction and operational support.