January 27, 2026 • 4 min read

The essential role

of water for renewable

natural gas

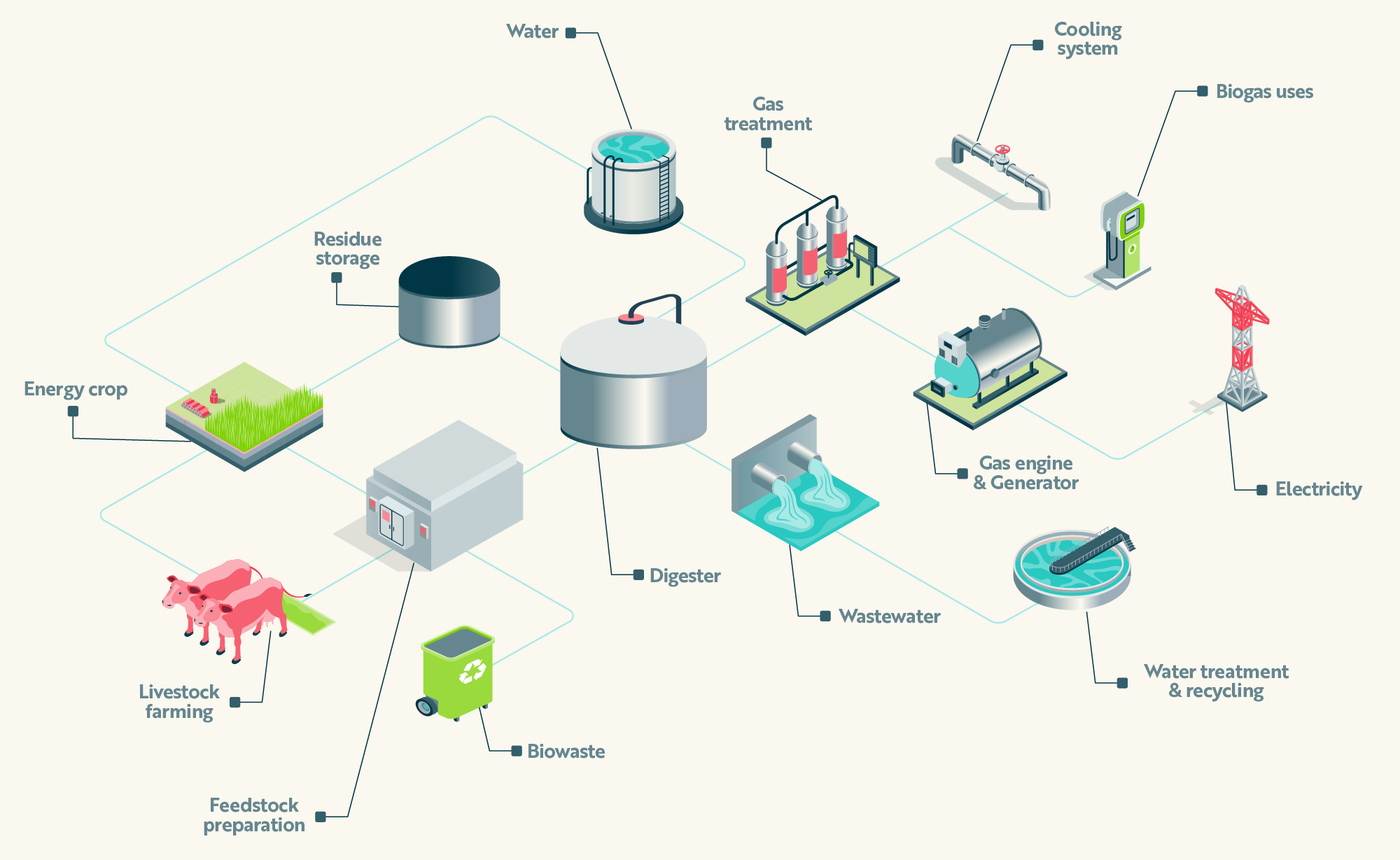

Anaerobic digestion is a widely used method across the food and beverage, agriculture, and pulp and paper industries for treating wastewater or reducing the volume of solids that require disposal. From low-tech lagoons to highly optimized tank-based systems, these technologies break down organic material and generate biogas — the feedstock for renewable natural gas (RNG).

Anaerobic digestion: From waste treatment to value creation

Anaerobic digestion relies on aqueous conditions to facilitate the breakdown of organic matter. In this way, water supports a circular economy: wastewater is treated, biogas is recovered, and RNG production contributes to net zero goals by capturing and reusing energy that would otherwise be lost. Rather than RNG being produced by water, anaerobic digestion relies on aqueous conditions to facilitate the breakdown of organic matter.

Historically, these systems were designed primarily to treat wastewater and produce a stable, safe by-product. Biogas was considered a bonus. The focus was on reliability and low-cost operation, not gas yield. But that’s changing.

With growing demand for RNG, today’s anaerobic digestion systems are designed for more than treatment – they’re engineered for performance.

This includes maximizing biogas yield, reducing parasitic loads, and recovering value from digestates and process residuals. Even carbon dioxide – once treated as waste – is now recognized as a potentially valuable source of biogenic CO2. When combined with green hydrogen, biogenic CO2 can be converted into low-carbon fuels like methanol.

Hover to zoom. Click to view larger (opens in a new tab). Tap to view larger (opens in a new tab).

This evolution reflects a broader trend: moving from waste management to value creation. And at the heart of it is not only water, but also solid waste or slurry. Maintaining the correct solids‑to‑water ratio (typically 8–12 percent total solids for wet digestion) is essential for microbial stability and process efficiency.

What exactly is RNG?

Biogas is typically derived through the anaerobic digestion of organic waste. This takes place when water and organic waste products, such as animal waste, field residues and other organic waste, are processed using naturally occurring bacteria in an oxygen‑free, aqueous environment. Unrefined biogas is produced during decomposition.

Recent developments have made it feasible to upgrade biogas. The resulting product is chemically identical to traditional fossil fuel-derived natural gas, but the feedstock is renewable. Hence the name renewable natural gas.

RNG is suitable in all applications where natural gas is used. Typical upgrading technologies include water scrubbing, pressure swing adsorption, and membrane separation, which remove CO2, H2S, and moisture to achieve >96 percent methane purity.

Making renewable natural gas from waste has been a core part of waste and wastewater management for more than a century, driven primarily by environmental performance and project economics.

The scale and pace of producing RNG has increased significantly over the past 10 years, driven by demand for green energy, carbon credits and government incentives, such us California’s Low Carbon Fuel Standard (LCFS) or the U.S. Renewable Fuel Standard (RFS).

Focus on front-end planning and operations

Many RNG facilities don’t meet their original gas yield forecasts. Often, production starts strong, then declines as solids build up in the digester. This can be solved through optimized designs that focus on conversion of feedstock to gas yield, to minimize the buildup of inert solids.

Systems that optimize feedstock conversion and reduce inert solids build-up deliver more consistent results.

Gas production can be highly variable as the seasons change. The challenge of meeting off-taker expectations can be solved through feedstock inventory management and improved feedstock pre-processing, such as briquetting. Pre-treatment options also include thermal hydrolysis, mechanical pulping, or enzymatic additives, which can improve biodegradability and boost gas yields.

Higher than expected operations and maintenance costs can be managed by maximizing feedstock conversion, dewatering feedstock and removing high-performance solids. Solids management strategies such as grit removal, sand traps, or improved sludge handling reduce wear on pumps and extend digester uptime.

Odor is a key concern for nearby communities – and one of the top reasons facilities face pushback or even shutdowns.

Careful design and operations that minimize leaks and fugitive emissions are essential.

We help our customers take a proactive approach to environmental concerns, including odor, noise, and traffic. Technologies such as biofilters, activated carbon units, or enclosed flare systems can mitigate odor issues.

Safety is also critical, especially with lagoon-style digesters, which can pose serious risks like explosion, suffocation, or drowning.

By applying the same standards used across the energy industry, we help design safer, high-performance facilities from the ground up.

Adherence to standards such as NFPA 820 and OSHA 29 CFR 1910 is key to ensuring worker and community safety.

Where RNG expertise meets practical delivery

We’ve worked on over 100 projects where renewable natural gas is produced – from purpose-built systems to multi-objective infrastructure upgrades. One example is our work with the Brisbane Water Enviro Alliance, where we helped upgrade four wastewater treatment plants to support a growing city.

We’re continuously improving on every project. And we bring those lessons to each new challenge. Whether you’re planning, designing, building or operating an RNG facility, we offer proven advisory, engineering, construction and operations support.