October 27, 2025 • 2 min read

Simplifying subsea tiebacks with pseudo dry gas in Australia

Investigating how we can reduce costs and improve overall performance for a long shallow water tieback system.

Faced with the challenge of optimizing a planned gas flow system, a customer came to us looking for a solution that could reduce costs and enhance production reliability.

While working with a customer in Australia on a new onshore plant, our Offshore Energy team was approached to conduct a study to investigate if a Pseudo Dry Gas (PDG) solution could reduce expenditure and improve production risks on their planned subsea tieback system.

Statistic Cards

Balancing cost and operations for smarter performance

The project involved connecting an offshore gas reservoir to an onshore facility, but it came with some major cost and operational hurdles.

Due to the length of the pipeline to shore, the customer had to invest in expensive liquid management equipment, such as a large slug catcher to handle rapid surges of liquid. There was also a risk that water could start flowing from the well earlier than expected, which could reduce total gas production capacity.

We also discovered that the performance of the corrosion inhibitor system was being pushed beyond comfortable industry practice. This raised concerns of a higher corrosion rate, risking a design change to a corrosion resistant alloy.

Pivoting to deliver better production capability

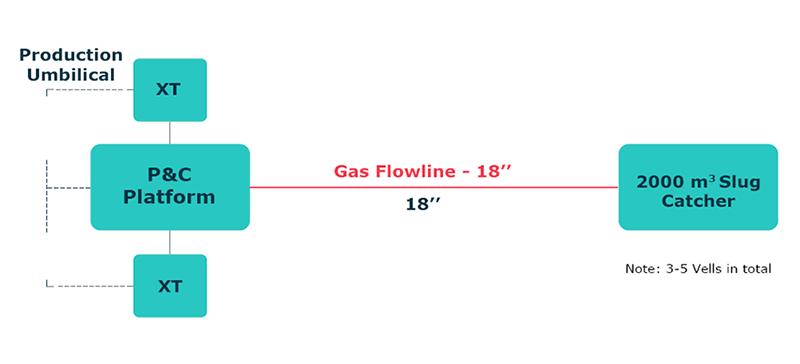

The customer’s original plan included a 300km gas export subsea pipeline.

At the end of the flowline was a 2,000m3 slug catcher onshore, while a remote offshore platform and high‑integrity pressure protection system were placed infield to provide the necessary power and communications systems. This solution, however, was proving to be complex and expensive.

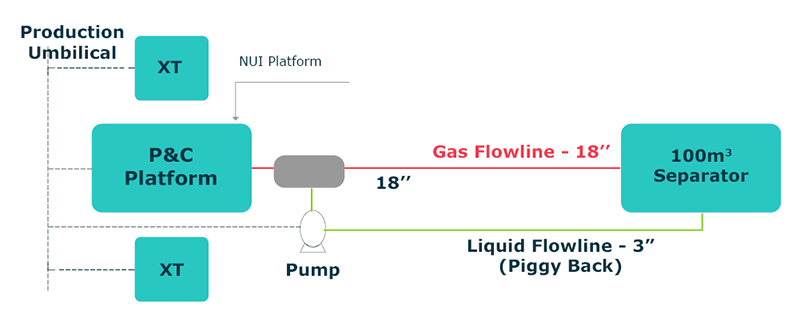

Through our study, we designed a PDG solution to provide an affordable alternative. By adding a smaller liquid flowline piggyback connected to customized pumps, we would be able to reduce the slug catcher size to 100m3 and increase gas throughput by almost 30 percent without a change of diameter – reducing costs from day one.

The new PDG field development plan would also make production more reliable, reducing back pressure and corrosion inhibitor requirements for a system better designed to handle produced water, achieving higher overall gas recovery.

Reducing complexity, increasing reliability

If implemented, our PDG solution could simplify operations, reduce pigging requirements and mitigate the use of compression, helping to lower Scope 1 and 2 emissions compared to the customer’s original design. The result: a safer, more reliable system with significantly lower capital cost and higher production performance.