Sustainable

Aviation Fuel

Aviation Fuel

Aviation is one of the hardest sectors to decarbonize. By 2030, sustainable aviation fuel (SAF) is projected to supply up to seven percent of global demand. Reaching net zero by 2050 will require approximately 400 million tonnes of SAF worldwide. Meeting that demand depends on new technologies, integrated approaches and global collaboration across the value chain.

Statistic Cards

Our approach to SAF project delivery

SAF production pathways

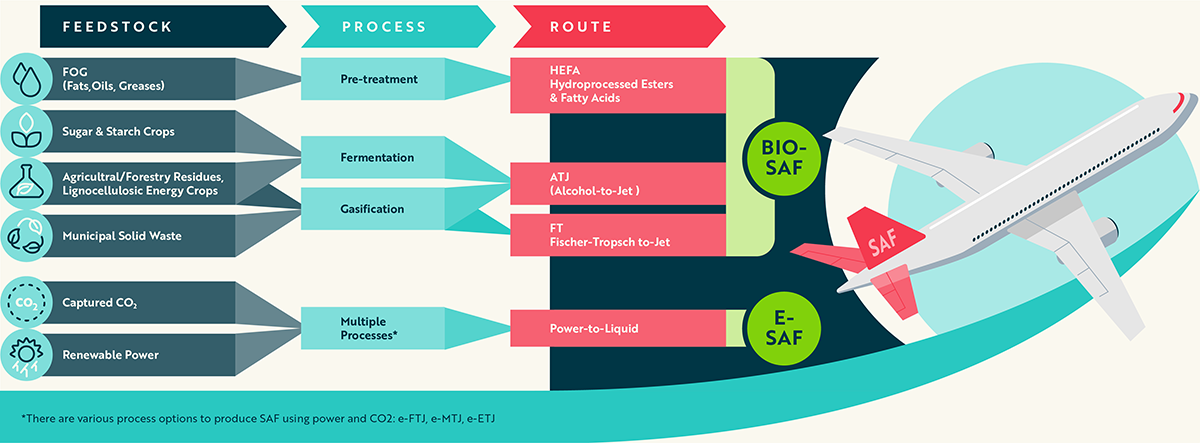

SAF can be produced through four primary technology routes, each determined by feedstock characteristics and conversion processes.

Hydroprocessed Esters and Fatty Acids (HEFA) Converts lipid-based feedstocks such as fats, oils and greases through hydro processing to produce jet-range hydrocarbons.

Alcohol-to-Jet (AtJ) Converts sugars and starches through fermentation followed by upgrading to jet-range hydrocarbons.

Fischer-Tropsch (FT) Uses gasification of biomass or municipal solid waste to produce syngas, which is catalytically converted into synthetic jet fuel.

Power-to-Liquid (PtL) An e-SAF pathway that combines captured CO₂ with renewable hydrogen through electrochemical and catalytic processes to produce synthetic hydrocarbons.

Power2X is developing a world‑scale e‑SAF production hub in Rotterdam using imported green methanol made from green hydrogen and biogenic carbon. Designed to be a major driver of Europe’s e‑SAF supply, the facility targets more than 250,000 tonnes per year of synthetic, non-fossil aviation fuel.

We’re delivering early engineering services, including a Class III estimate and preliminary design, to help define the optimal execution strategy for FEED and execution phases shaping this complex energy-transition project. Our work involves applying proven technical knowledge to reduce risk, improve CAPEX certainty and secure a robust schedule.

The hub will support compliance with ReFuelEU Aviation regulations and is projected to supply 40 percent of Europe’s e‑SAF volumes.

Critical success factors in scaling SAF – and how we address them

Every SAF project faces shifting economics, regulations, technology, and feedstock. Addressing these challenges early is the key to building resilient strategies and keeping progress on track.

Business case clarity Scenario planning, demand outlooks and sensitivity modeling to build decision‑ready economics.

Funding confidence Levelized‑cost analysis, CAPEX/OPEX ranges and risk registers to support lenders and investors.

Cost and schedule predictability Class III estimates and stage‑gate planning; execution strategies aligned to supply‑chain and permitting realities.

Risk allocation frameworks Tailored models across owners, licensors, EPC and off‑takers; commercial terms mapped to delivery risk.

Technology choice Comparative assessments (TRL/FRL, feedstock fit, carbon intensity, scale) and licensor engagement.

SAF pricing and off‑take Contract structures matched to pathway and region; integration with airline/ off‑taker requirements.

Feedstock availability Supply‑chain mapping, logistics studies and sustainability metrics to secure volumes and carbon profile.

Policy and compliance Monitoring of mandates and incentives; pathways aligned to ASTM and regional frameworks (e.g. ReFuelEU).

Our SAF experts

1. What is sustainable aviation fuel (SAF)?

Sustainable aviation fuel (SAF) is a drop-in alternative to conventional jet fuel produced from renewable or recycled feedstocks, including fats, oils, greases, biomass, waste and captured CO2. SAF can help aviation reduce lifecycle emissions compared to fossil-based jet fuel, depending on the pathway and feedstock used.

2. How does SAF help aviation move toward lower carbon operations?

SAF has the potential to reduce lifecycle greenhouse gas emissions when compared with conventional jet fuel. The reductions vary by pathway, feedstock and technology. It’s one of the most viable near-term options available to help decarbonize aviation while existing aircraft and infrastructure remain in use.

3. What are the main SAF production pathways?

The four primary SAF pathways are Hydroprocessed Esters and Fatty Acids (HEFA), Alcohol‑to‑Jet (AtJ), Fischer–Tropsch (FT) and Power‑to‑Liquid (PtL/e‑SAF). Each pathway has different feedstock requirements, technology maturity levels and scalability considerations.

4. What are the biggest challenges in scaling SAF production?

Key challenges include feedstock availability, technology selection, capital costs, regulatory certainty, off-take agreements and project delivery complexity. Understanding these early can improve project viability and long-term performance.

5. How does Worley support customers developing SAF projects?

We help customers across the full lifecycle, from feasibility studies and technology evaluation to engineering, procurement and project delivery. Our teams bring experience across all commercial SAF pathways, supporting cost certainty, schedule confidence and risk reduction.

6. Is SAF compatible with existing aircraft and airport infrastructure?

Yes. Most SAF produced today meets ASTM D7566 specifications, enabling it to be blended with conventional jet fuel and used in existing aircraft without modifications. Blend limits depend on the specific SAF pathway and certification.

7. What feedstocks can be used to produce SAF?

SAF can be produced from lipid-based feedstocks (fats, oils and greases), sugars and starches, biomass, municipal solid waste and captured CO2 combined with renewable hydrogen. Feedstock availability, cost and sustainability attributes influence pathway selection.

8. How quickly is global SAF demand expected to grow?

Demand for SAF is rising due to airline commitments, regional mandates and net-zero targets. By 2030, SAF is expected to meet roughly 5–7 percent of global aviation fuel demand, with significant scale-up needed through 2050 to align with industry pathways to net zero.