October 09, 2025 • 3 min read

AI digital twins are redefining industrial work

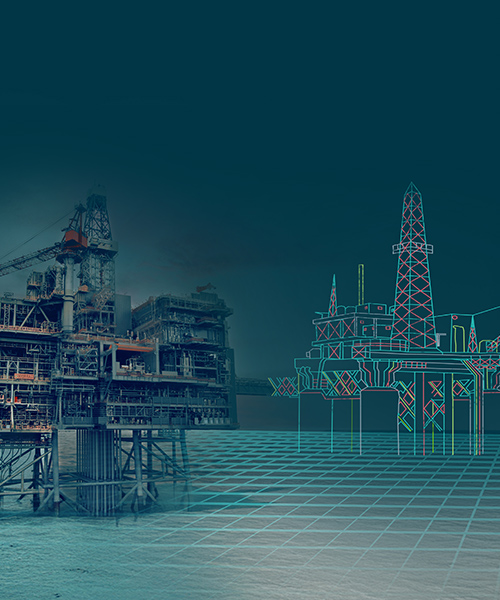

In industrial sectors, ‘digital’ used to mean dashboards, sensors, and analytics – tools that help us understand the work. But today, digital is doing more than supporting operations. It’s starting to redefine them.

At the heart of this shift? The rise of AI-powered digital twins.

AI-powered digital twins are no longer just mirrors of reality, They’re engines of transformation.

Beyond simulation: Digital twins as decision engines

Digital twins began as virtual replicas of physical assets and processes – helping us monitor performance, predict failures, and optimize maintenance.

Now, with AI, they’re evolving into autonomous systems that simulate future scenarios, recommend actions, and even initiate responses without human input.

Key shifts:

- AI models learn from historical and real-time data.

- They simulate scenarios, recommend next steps, and trigger automated actions.

- Teams move from reactive to proactive, predictive, and prescriptive ways of working.

An exponential leap in value

The shift from simulation to autonomy isn’t incremental. It’s exponential.

For example, in energy production, a digital twin can analyze turbine sensor data, anticipate wear, and schedule repairs before issues occur. This helps reduce downtime, increase safety, and unlock efficiency. Even a 1% optimization can drive measurable gains over the life of an asset.

Redefining roles, not replacing people

This evolution isn’t just technical – it’s cultural.

“Digital tools used to be something we used,” says Hodson. “Now, they’re becoming partners we collaborate with.”

The implications for industrial teams are significant:

- Roles are changing: Engineers are becoming orchestrators of intelligent systems, not just operators.

- Skills are evolving: Data fluency, systems thinking, and AI literacy are now core competencies.

- Processes are reimagined: From design to maintenance, workflows are being rebuilt around digital-first principles.

Human-machine collaboration

As digital twins become more intelligent, the line between human and machine decision-making starts to blur.

Machines handle routine analysis and repetitive tasks. People focus on strategy, creativity, and oversight.

“This partnership amplifies human potential. It helps us move faster, build resilience, and make smarter decisions.”

The new digital mindset

To make the most of this shift, energy, chemicals and resources companies need to think differently:

- Digital isn’t a layer. It’s a foundation.

- AI isn’t a tool. It’s a collaborator.

- Transformation isn’t a one-off project. It’s a continuous capability.

- This requires leadership commitment, investment in digital infrastructure, and a culture of experimentation and skills development.

“The real question isn’t ‘How can digital help us do our work better?’”, says Hodson. “It’s ‘How is digital redefining what our work is?’”

Overcoming barriers

Transformation doesn’t happen without friction and challenges.

Legacy systems, data silos, and resistance to change can slow progress.

Success depends on clear leadership vision, investment in digital infrastructure, robust change management and a culture of learning, experimentation and iteration.

A bridge between legacy and future

This transformation is especially relevant for teams in manufacturing, energy, infrastructure, and logistics. They have high-value assets, complex systems and legacy processes – but also huge potential for reinvention.

AI-powered digital help by:

- Integrating data across silos

- Simulating systems, not just components

- Supporting confident, faster decision making.

“It’s not about tech for tech’s sake,” says Hodson. “It’s about helping people do their best work.”

Real world impact

Consider a logistics company using digital twins to model its entire supply chain. AI analysis weather patterns, traffic data and inventory levels to optimize delivery routes in real time. The result: reduced costs, improved customer satisfaction and a more sustainable operation.

In infrastructure, digital twins can simulate the impact of new construction on existing assets, helping planners make informed decisions and avoid costly mistakes.

Looking ahead: The future of digital twins

Digital twins will continue evolving. We’re moving toward ecosystem twins – integrated, intelligent models of entire organizations and industries.

“We’re heading toward a future where digital twins don’t just reflect operations,” Hodson says. “They reshape them.”

To stay ahead, industrial leaders must embrace continuous transformation, invest in digital talent and cultivate a culture of collaboration. The leaders of tomorrow will see digital twins not just as a technology, but as a catalyst for reimagining work itself.

AI-powered digital twins are shifting digital from support act to strategic partner. The organizations that lean in will lead the way – unlocking new agility, resilience, and innovation.