February 03, 2021 • 2 min read

Designing and engineering Velocys' Altalto facility

How we're helping to deliver Europe’s first waste-to-sustainable aviation fuel (SAF) plant

Rubbish. It’s not the first thing that springs to mind when making sustainable transformation a reality. But imagine a world where there was a 70 percent reduction in greenhouse gases when planes flew from A to B, compared to planes of the past. Or a 90 percent reduction in particulate matter from engine exhausts. Or 500,000 tonnes of waste diverted from landfill. Or all three?

We’re working alongside sustainable fuels technology company Velocys to turn this into a reality – reducing greenhouse gas emissions and minimizing the sulphur content in the fuel to almost zero.

“Aviation and heavy goods transport remain the hardest sectors to decarbonize,” explains Velocys Chief Executive Henrik Wareborn. “Passenger vehicles can be electrified, but airplanes and trucks require much higher energy density. Low-carbon fuels are essential to achieve net-zero targets in these sectors.”

Creating clean-burning fuel for everyone

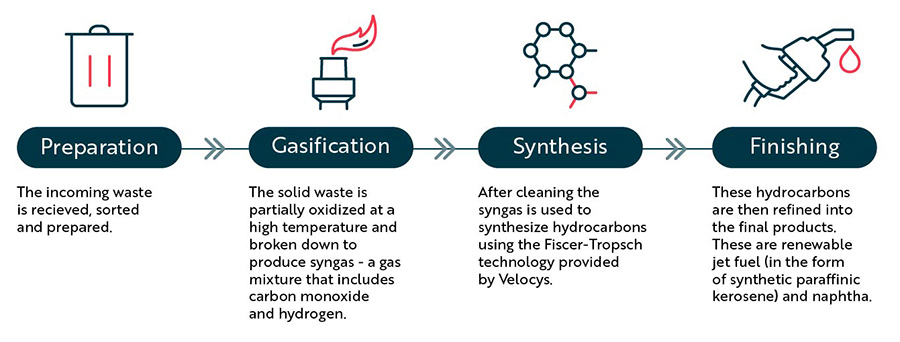

We’re delivering the pre-feasibility, feasibility and front-end engineering and design packages for what will be Europe’s first waste-to-jet-fuel plant in Immingham, North East Lincolnshire, close to the Humber estuary. The Altalto facility will turn municipal solid waste into clean-burning fuel for both the aviation and vehicle industry.

When the plant is operating it will receive hundreds of kilotonnes of waste every year, which was destined for landfills or incineration, and create sustainable fuel. The fuel will meet regulatory standards and can be used in planes and road vehicles without engine modifications being needed.

Taking clean jet fuel global

We’re not just doing this in the UK. Once this facility is operational – targeted for 2025 subject to funding – we will work with Velocys to use the same technology to design and build other plants around the world. There will be a plant in the US that will process waste from the paper and lumber industries (biomass forest residue) into renewable fuels for transportation.

“The transition to sustainable aviation fuel is within reach,” says Bradley Andrews, President for Worley UK, Norway, Central Asia and Eastern Europe. “This provides us with a potential path to cut emissions significantly and meet long-term decarbonization goals. It’s an exciting time to partner with Velocys as we take steps to help make this a reality at the Humber and other global sites in the future.”

Statistic Cards

liters of sustainable jet and road fuel every year

tonnes of waste diverted from landfills

tonnes of estimated net CO2 savings every year