December 04, 2025 • 3 min read

Turning battery waste into value: Solving the sodium sulphate challenge

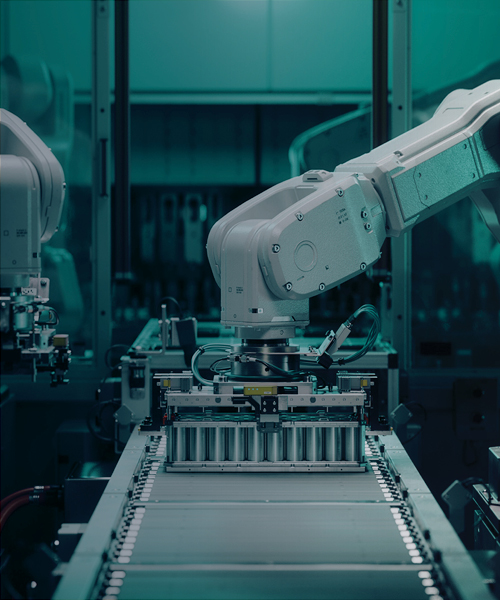

In 2023, batteries outpaced every other energy technology, with deployment more than doubling and electric vehicle battery use increasing by 40 percent.1

The sector’s momentum is clear. But this growth brings a hidden challenge.

“Every tonne of lithium, nickel or phosphate processed for battery materials creates byproducts like sodium sulphate in significant volumes,” says Jonathan Radcliffe, Specialist Process Technologist, Worley Consulting. “Traditionally, sodium sulphate is discarded or used in low-value applications. But as the demand for batteries grows, so does its volume across the battery supply chain.”

What if we could turn this waste stream into something valuable?

A growing waste stream in a growing industry

Sodium sulphate is created at multiple stages in the battery materials supply chain – from the acid roast process to refine spodumene to producing iron phosphate for lithium-iron-phosphorous (LFP) cathodes, precursor production for nickel-manganese-cobalt (NMC) cathodes and black mass recycling.

“Historically, producers disposed of this byproduct or used it in household products like detergents and washing powders,” explains Radcliffe. “But with battery demand booming, the volume of sodium sulphate that’s being created is exceeding its need for this use, creating both environmental and economic issues for the industry.”

Solution: Bipolar electrodialysis

Working with technology vendors in Europe and China, we’re exploring how to turn this challenge into an opportunity using bipolar electrodialysis (BPED), an advanced electrochemical process that splits sodium sulphate into sulphuric acid and sodium hydroxide (Na2SO4 + 2H2O → H2SO4 + 2NaOH).

“In simple terms, BPED uses an electric current to separate salts into acid and caustic, creating two reagents that can be reused in the battery precursor production,” explains José Ruiz, Principal Specialist Process Engineer, Worley Consulting.

It’s a circular economy approach, as it converts waste into inputs for the processes that produced it.

“BPED lets us reimagine waste streams as part of the value chain, improving efficiency while reducing impact,” says Radcliffe. “We’re supporting customers with concept and feasibility studies, including CAPEX and OPEX estimates, reagent cost savings and financial modeling to evaluate commercial viability.

“Our goal is to implement this technology at an industrial scale.”

Pilot projects in Europe and China demonstrate commercial feasibility.

A viable, valuable path forward

After early feasibility and pilot studies, we’ve found that BPED is a practical, scalable solution for the battery materials industry.

“With increasing efficiency and lower costs, proven performance and process compatibility and purity, BPED delivers measurable economic and environmental benefits based on our experience and what we have seen in the market, ” says Ruiz.

Lower BPED equipment costs with higher efficiency

BPED systems now deliver higher concentrations of acid and caustic.

“This reduces the size and cost of downstream concentration plants, improving project economics. Compared to earlier studies that we conducted in 2024, we’ve seen overall CAPEX savings that can reach up to 50 percent,” explains Ruiz.

Proven performance at scale

Demonstration-scale systems in Europe and full-scale systems in China show BPED is an industrially viable option.

“These facilities show stable operation, consistent product quality and measurable reagent recovery benefits,” says Ruiz.

Process compatibility and purity

“Our calculations show residual sodium sulphate levels in the acid and caustic streams after concentration are below solubility limits,” says Ruiz.

This means no unwanted crystallization of the sodium sulphate is expected during evaporation. Vendors of BPED systems have confirmed this.

Ruiz continues. “Importantly, BPED also delivers sulphuric acid with fewer impurities than commercially available reagents. This is critical for cathode precursor manufacturing.”

Economic and environmental benefits

By regenerating reagents onsite, producers can stabilize supply, reduce exposure to volatile prices for acid and caustic reagents and cut transport emissions.

“In a sector where margins and sustainability matter, BPED can offer a more stable and economically attractive alternative due to the savings in reagents costs.” José Ruiz

“This is despite it needing more CAPEX than the crystallization and drying process to produce sodium sulphate crystals for the fertilizer industry and other applications,” says Ruiz.

Beyond batteries

BPED’s potential extends beyond the battery value chain. “Successful test work on effluent streams from the textile sector shows its versatility across other industries,” says Ruiz.

Making sustainable transformation a reality

By turning a waste stream into a resource, we’re helping customers to improve project economics and process efficiency and to contribute to a more sustainable battery supply chain.

“As the battery value chain evolves, technologies like BPED could redefine how materials are sourced, reused and reimagined,” says Radcliffe. “As industries decarbonize, we need to continue to think differently about waste. BPED shows how sustainability and profitability can go hand in hand.”